Stainless steel tubes.

WIDE RANGE FOR ALL VARIANTS.

WELDED.

Welded with

TIG/LASER or with

HF (high frequency) welding.

Standard bars L=6mt

Welded with

HF (high frequency) welding.

Standard bars L=6mt

Welded with

HF (high frequency) welding.

Standard bars L=6mt

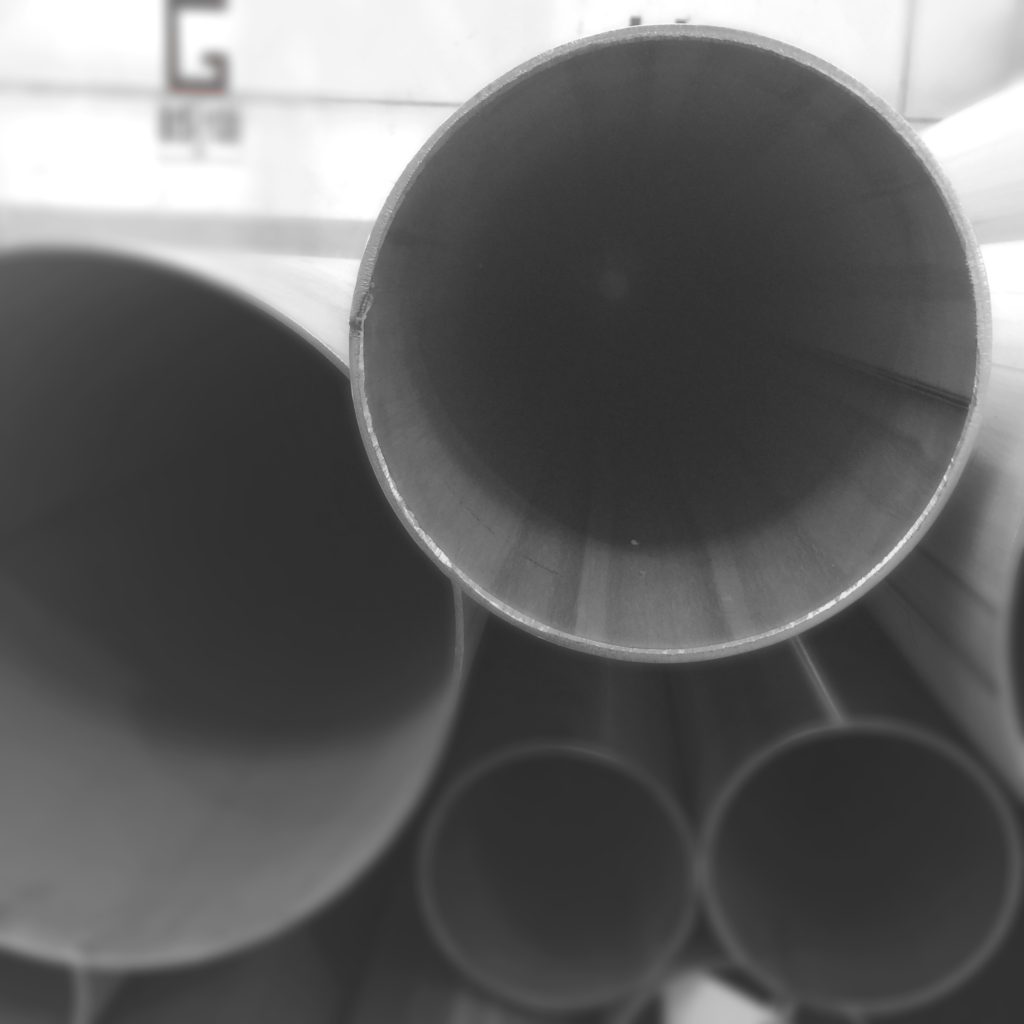

Stainless-steel welded tube is part of the most widespread stainless-steel products.

The stainless-steel tube is produced by roll forming of specially trimmed strips/coils by subsequent welding in line withTIG (Tungsten Inert Gas), Laser or HF (High Frequency) methods. The welding bead can be removed by scarfing tools where the diameter permits.

The starting strip can be cold-rolled (generally up to a thickness of 1.5/2 mm) or hot-rolled (from 2 mm upwards) thus determining the surface appearance of the stainless-steel tube.

Stainless steel tubes are also available in different finish. The satin-finished stainless-steel tube is often used for aesthetic/furniture purposes and is obtained by surface abrasion on request (the standard of the satin-finished tube is 240/320 grit depending on the diameter).

Another very common finish in the food/pharmaceutical but also naval appliances is the polished stainless-steel tube protected with a PVC envelope for each individual bar and obtained by brushes and special polishing pastes or in some cases obtained from a specific polished starting coil with careful working of the weld roughness (food industry use).

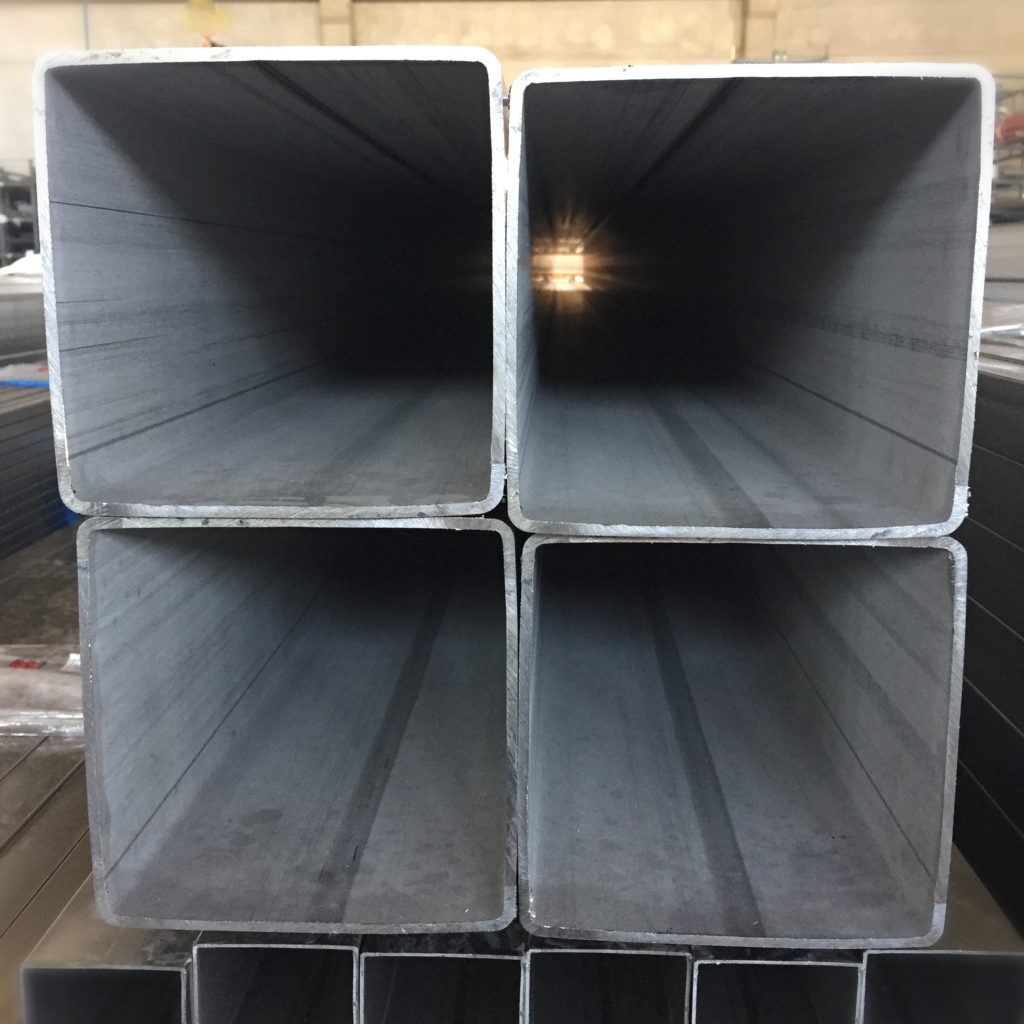

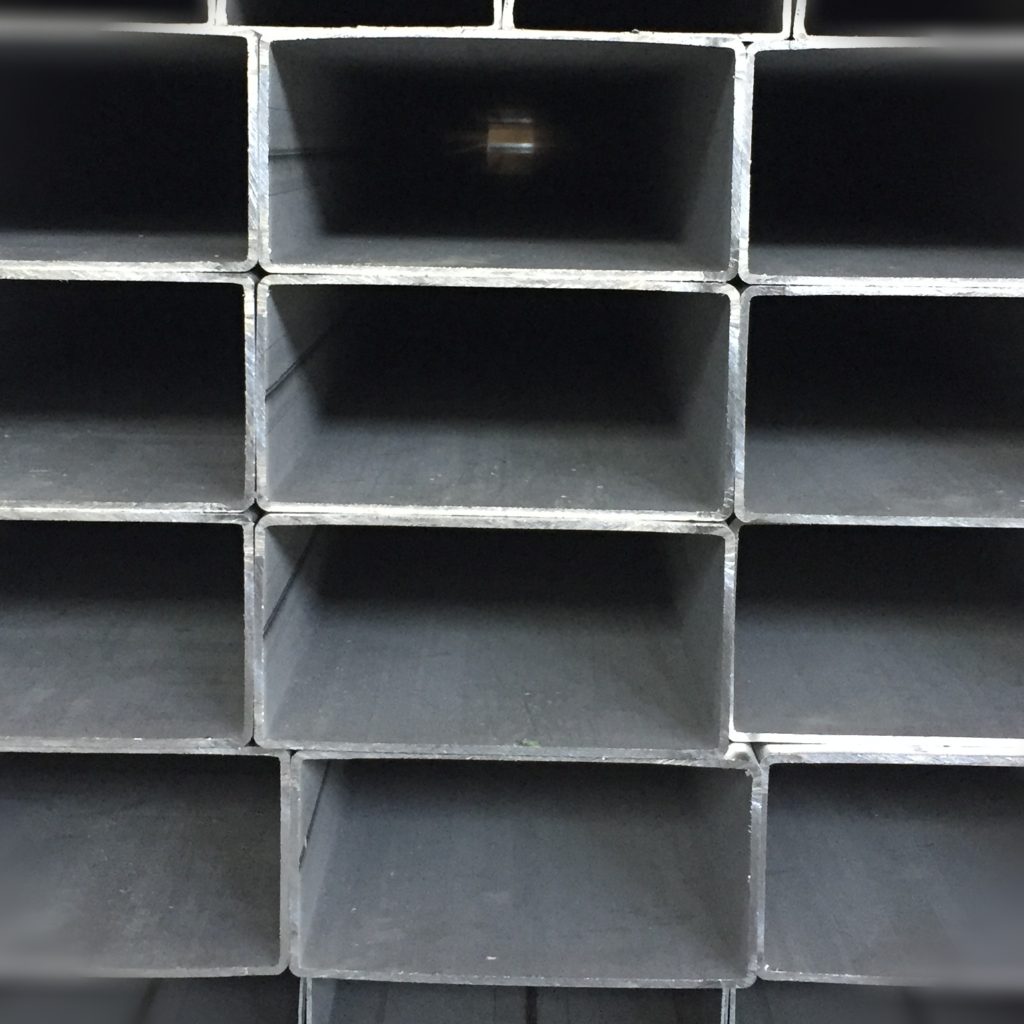

Stainless steel square tubes, like stainless steel rectangular tubes, are generated by reprofiling stainless steel round tubes. Satin or polished finish in addition to the standard brushed finish is also available.

The entire range is commercially produced in AISI 304, AISI 316 stainless steel or in special cases steels such as AISI 441 and AISI 430. (See the Steels tab).

The stainless-steel tube is accompanied by appropriate certification if required.

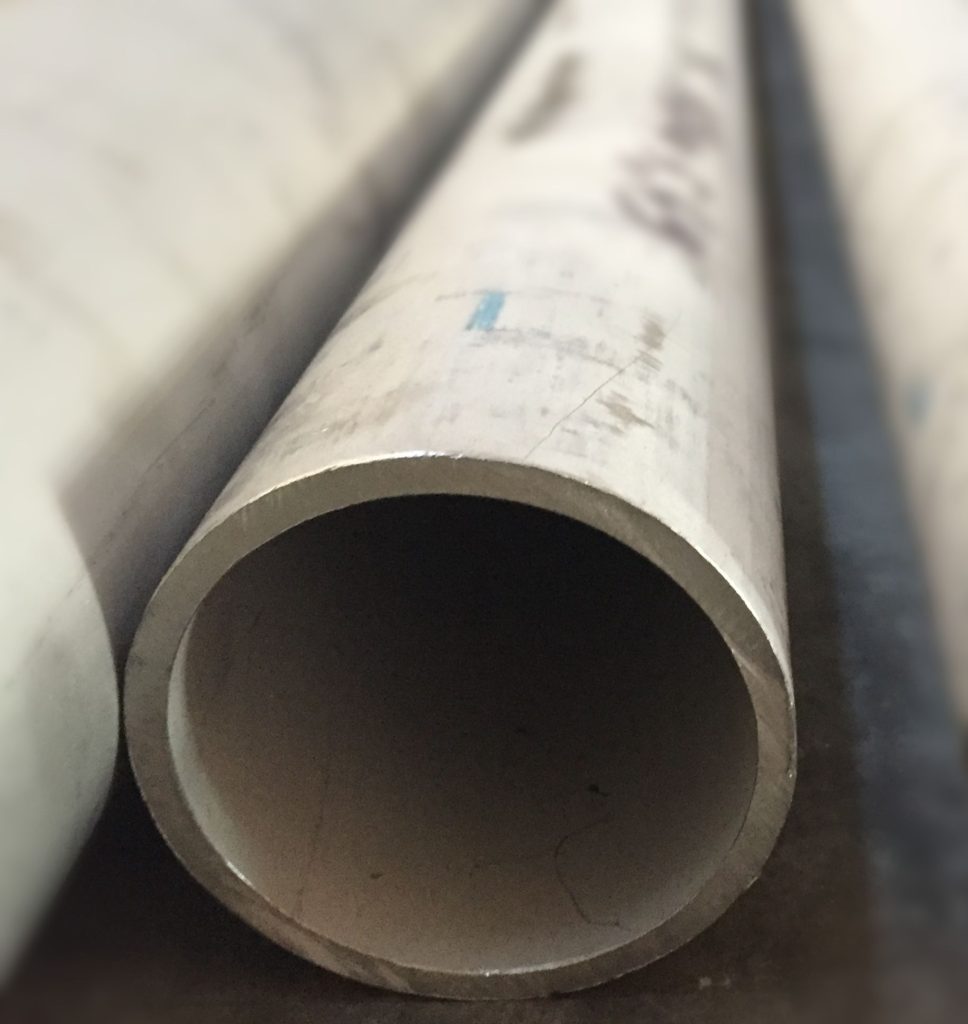

SEAMLESS.

The stainless-steel seamless tube (also called SS) originated for petrochemical uses or high-pressure conditions but is now also used for different purposes such as load-bearing structures or machining.

Stainless SS pipe (seamless or ASTM/ANSI pipe) has a rough surface finish (aluminium colour) and wide manufacturing tolerances. Bars vary in length from 5.5 m to 6.5 m, but for special applications, such as heat exchangers, custom lengths can also be produced. It is normally marketed in AISI 304 or AISI 316 stainless steel.

The most commonly marketed seamless stainless-steel tube follows diameters mainly in inches and thicknesses defined by schedules.

The commercial schedules are 5s, 10s, 40s and 80s. Each schedule corresponds to an exact nominal thickness.

PERFORATED BAR. MECHANICAL TUBE.

The stainless-steel perforated bar (also called mechanical tube) finds its main use in mechanics except in some particular cases of structural use.

The main processing method is lathe processing.

The stainless-steel mechanical tube (called perforated bar) has a very rough finish, in some cases it can also be ground externally. Bars vary in length from 4.5 metres to over 6 metres. For all sizes, cuts are made at the customer’s specific request. It is produced in AISI 304 and AISI 316 stainless steel.

The stainless-steel perforated bar is produced according to a special template, cast directly without welding. To meet its main use, it has very large thicknesses. The tolerances are very wide due to the nature of its use.