Stainless steel strips.

A WIDE RANGE FOR ALL VARIANTS.

COLD-ROLLED.

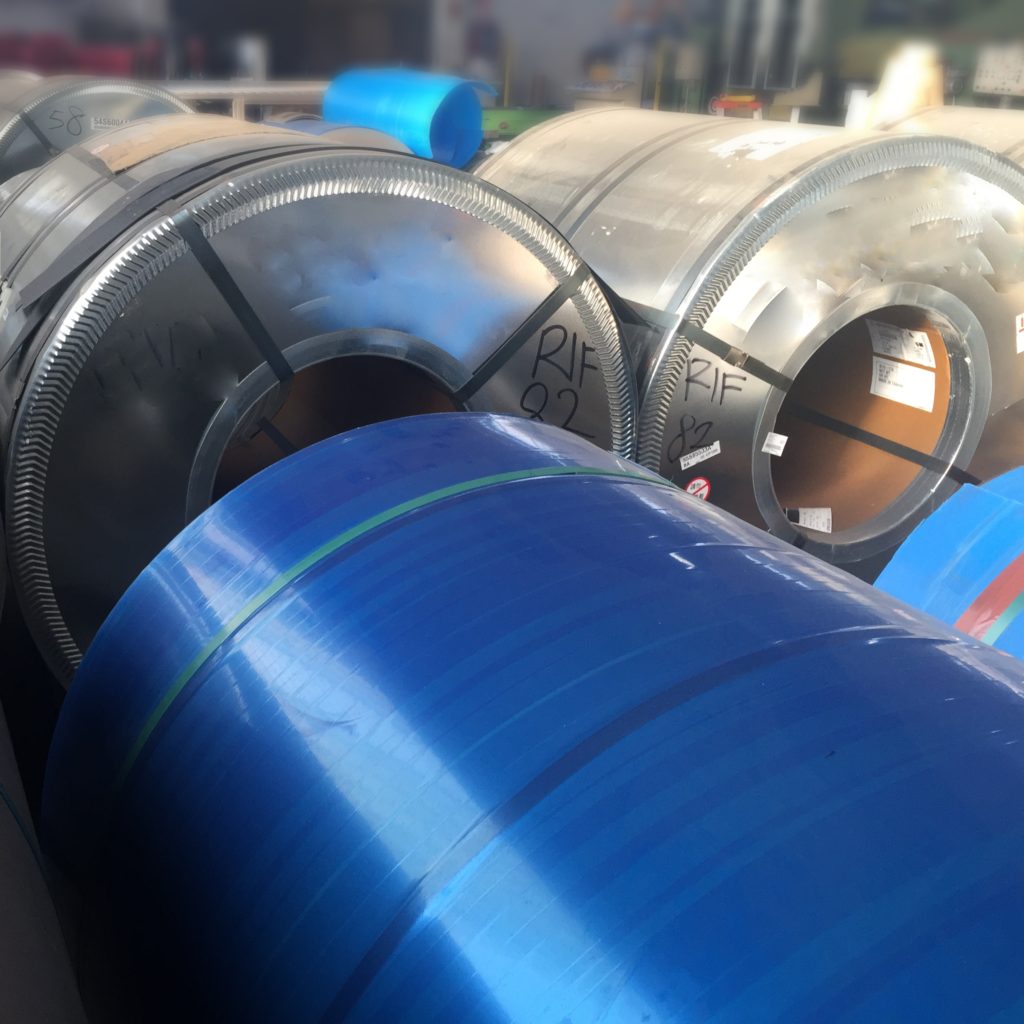

Stainless steel strip (coil) is the primary product generated by the steelworks: after casting, processed through the rolling mill, and then rolled into coils.

Stainless steel cold coil is obtained cold rolling the hot rolled coil, reducing its thickness and, if necessary, by surface treatment.

The range of cold-rolled strip is generally produced for fine thicknesses from 0.4 mm up to 8 mm.

The most common and sold finish is called 2b, obtained by cold rolling, but it is also possible to obtain the polished strip called BA (Bright Annealed).

All strips can be produced in AISI 304, AISI 316 and AISI 430 stainless steel.

HOT-ROLLED PRODUCTS.

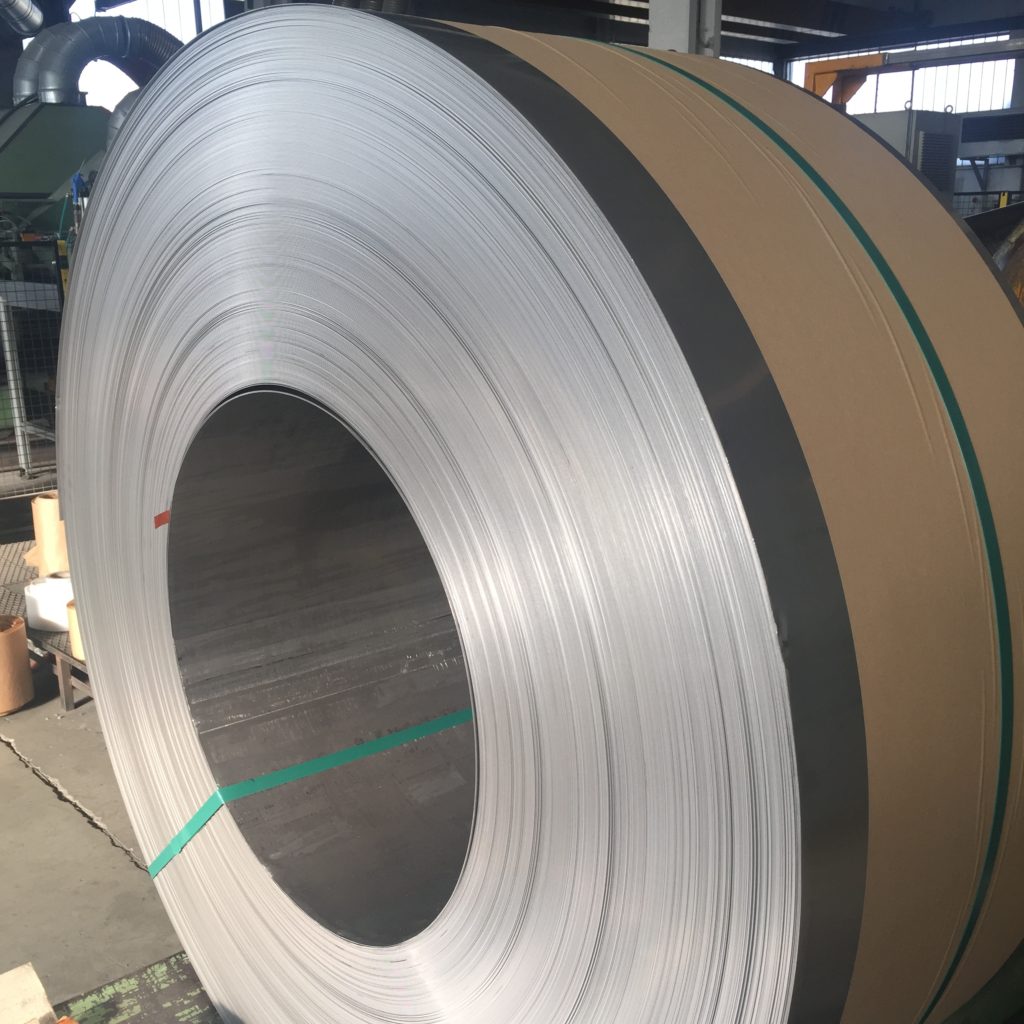

Stainless steel coil is the primary product generated by the steelworks, following casting, by subsequent processing, in the rolling mill, a continuous sheet is formed and then rolled into coils.

Stainless steel hot coil is obtained by rolling directly from the casting, progressively reducing its thickness.

Hot coil is generally produced for thicknesses from 2 mm to 12/15 mm.

The most common and widely sold finish is called F1.

All coils can be produced in AISI 304, AISI 316 and AISI 430 stainless steel.

MANUFACTURING.

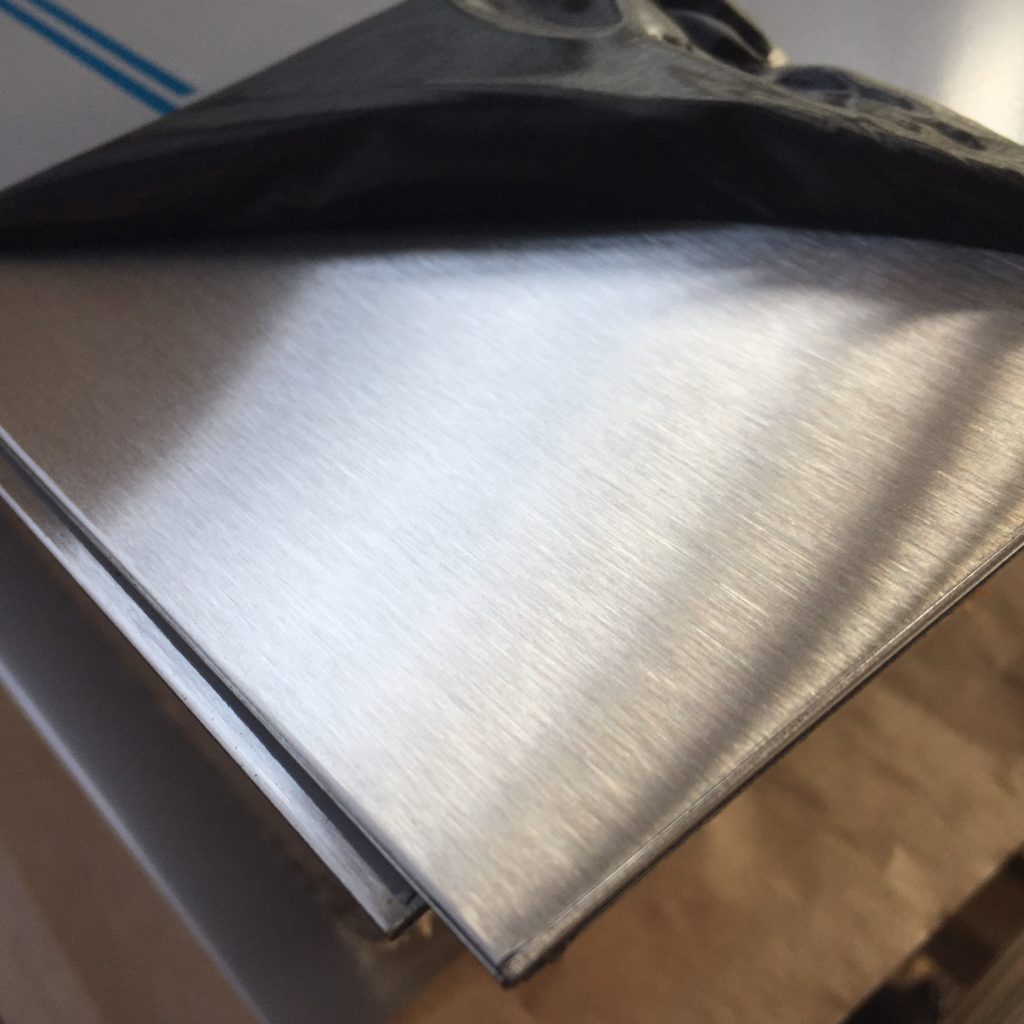

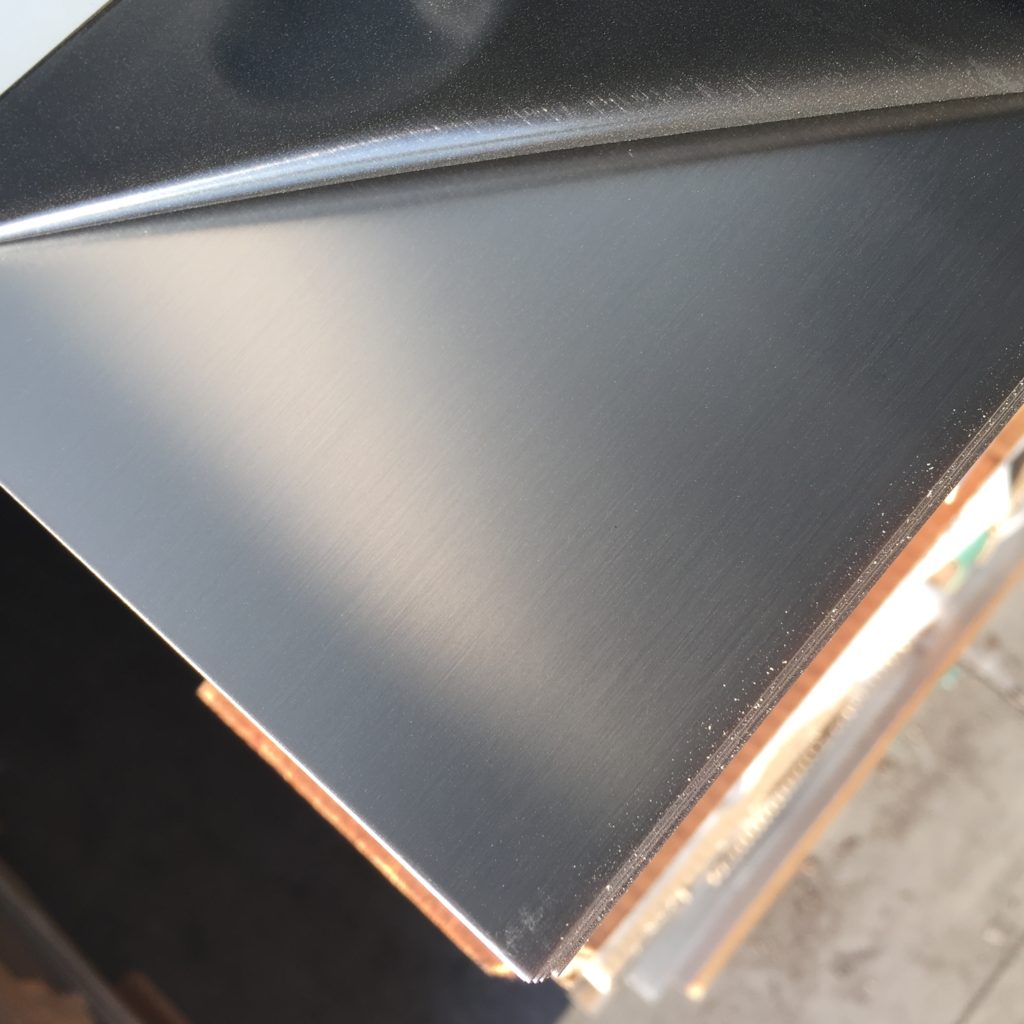

The surface finishes are carried out using special machines and gives them a dedicated aesthetic finish for a wide variety of uses.

Generally, after surface treatment, the strips are protected by a thin PVC film.

Processing is mainly carried out on coils/cold-rolled strips due to the excellent starting base typical of this product.

Carried out by means of special abrasive cloths, it gives the typical appearance that can be customised through the choice of grain (diameter of the glass beads of the cloths used). Following processing, the surface is generally protected with a PVC adhesive film at the customer’s request. The quality of the starting coil is crucial for the final result.

Carried out by means of special rotating drums made of abrasive material give the light brushing that appearance typical of scotch-brite. Following processing, the surface is generally protected with a PVC adhesive film at the customer’s request. The quality of the starting coil is crucial for the final result.

Carried out by means of cloth brushes and spraying of polishing paste, a bright and shiny (mirror-like) appearance is given. Following processing, the surface is generally protected with a PVC adhesive film at the customer’s request. The quality of the starting coil is crucial for the final result.